DSI-PBL® Bypass System Successfully Utilized by Middle East Operator in Split Flow Application

Overview

A major Middle East operator requested the DSI PBL Split Flow technology to be utilized during drilling of the 16“ section of oil production well in their current field, this section was to be drilled from a depth of 1,261 feet from 6 deg inclination to a depth of 5,805 feet to 46 deg inclination at section TD. The BHA consisted of an RSS and PBL circulating sub configured for the requested split of 75 % flow to BHA and 25 % flow through the PBL ports.

The hydraulic information provided by the client enabled DSI Engineering to calculate the feasibility of this configuration based on the collective parameters and conditions.

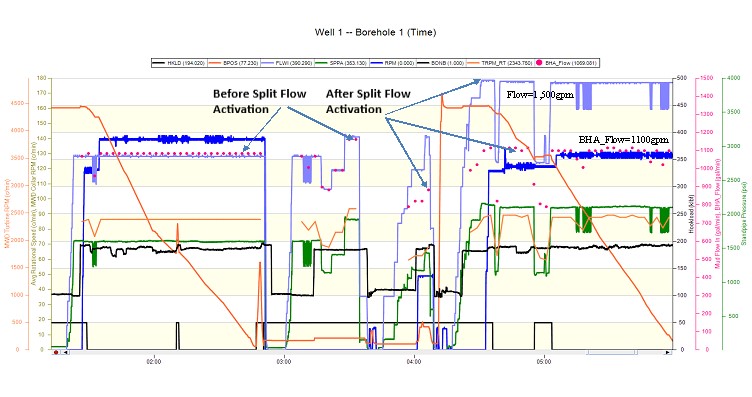

The application was designed to give 1,100 constant gpm to the BHA to generate the appropriate pressure drop to the RSS pads to enable optimum steerability. The split flow diverted through the ports of the PBL circulating sub would increase annular velocity to provide enhanced hole cleaning during the drilling process.

Results

- A downhole test was carried out at a depth of 1,454 feet at flow rates of 900 gpm (1,875psi), 1,000 gpm (2,148 psi), 1,100 gpm (2,343 psi) & 1,200 gpm (2,578 psi) and the pressure was recorded as a pre-split flow activation reference.

- Activation 1: At 1,454 feet, a patented DSI split flow dart was dropped & PBL Sub was activated. The flow recorder confirmed that the required split flow ratio of 25 % to ports & 75 % to BHA had been achieved and drilling operations recommenced.

- Deactivation 1: As this was a trial run and the first split flow application performed by DSI for this client, it was decided to cycle the PBL to prove the deactivation process and monitor the ease and simplicity of deactivation, at a depth of 3,831 feet deactivation procedure was followed & the tool reconfigured to 100 % confirmed flow through the BHA.

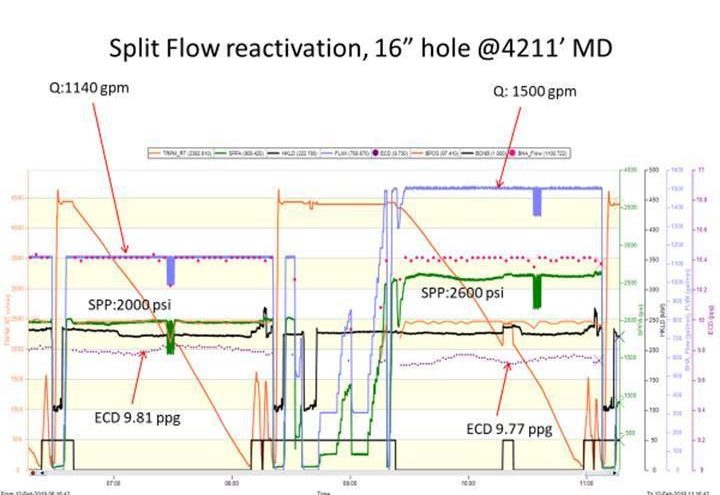

- Activation 2: At a depth of 4,211 feet a dart was dropped to activate the PBL and once again, a split flow of 75 % to BHA & 25 % to PBL ports was confirmed and the section was drilled ahead to a TD of 5,805 feet, the PBL was successfully deactivated and BHA was tripped out of hole.

- Testimonial from Drilling Engineer – “Works like a charm, 75 % flow through BHA, 25 % flow out through split flow tool. The in-house Directional Drilling engineer had made a spreadsheet to predict TRPM, and it works exactly as modelled.”

- The success of the PBL tool Split Flow operation on this well has led to interest from other rigs within this company and further requests have ensued.